training - consulting - facilitating

get answers to some common questions

Microbe Management

The most frequent and severe cause of food borne illness is through microbiological contamination. Microbes are not visible to the human eye and pose an unseen threat. They can contaminate foods at any stage of the supply chain, from on-farm through to consumer preparation in the home kitchen.

There are many microorganisms in the environment. Some are totally harmless, some are beneficial (such as those used in yoghurt and cheese making) and others are the cause of food spoilage and rotten fruit and vegetables. Only a small number of microorganisms are harmful to humans. These are called human pathogenic microorganisms and include species of bacteria, viruses, parasites and even types of algae and fungi.

Food borne illness symptoms can range from mild discomfort through to permanent damage to vital organs and death. The degree of impact depends on the type of organism, the infective dose (number of pathogens ingested), immune system functionality and the treatment options available for an infected person. Listed below are the key microbiological organisms that cause most food borne illness.

answers to some frequently asked questions about microbes in food

to find out more - simply click on the icon links on these pages or click on the documents to download the files

download Guidelines for On-Farm Food Safety for Fresh Produce

some microbes have strong associations with particular foods or thrive under certain conditions e.g. Bacillus cereus is associated with starch products and some Vibrio serovars are associated with seafoods

go to CPS for latest research on microbe survival in produce

go to Food Standards Code

microbes can form ‘biofilms’ on the surfaces of fresh produce and survive sanitation wash steps

search PUBCRIS chemical database for APVMA registered chemicals

Freshcare Food Safety and Quality Code 3rd Edition

the presence of fresh produce spoilage microbes (e.g. fungi, bacteria) is not a food safety issue

- it might be inedible but it probably is not unsafe

Contact your local council to find out where you can get your water tested.

Except for cultured seeds and grains (e.g. bean sprouts, alfalfa sprouts) there are no specified microbiological limits for fresh produce in the Australia New Zealand Food Standards Code Standard 1.6.1. However, the industry food safety programs and major customers have adopted testing levels of E.coli ≤10/g and Salmonella Not Detected/25g as acceptable microbiological levels. These are not regulatory food safety limits but action levels that, if exceeded, mean there is a contamination source in the system that requires investigation and control measures be put in place. Some customers specify additional food safety microbes to be included in the testing.

Microbe survival on produce

Microbes can be resilient if conditions are favourable and contamination in the field may survive on produce sold to consumers. Numbers of surviving microbes will depend on the initial contamination level, the availability of water and nutrient, competition from other microorganisms, environmental conditions, time from contamination to harvest and whether there are any decontamination steps applied to produce after harvest.

Produce types that are grown in or in direct contact with contaminated soil or water, have an edible skin and are generally eaten uncooked have a higher significance of risk for microbial contamination. These products will typically not encounter any ‘kill step’ before consumption. They include products such as leafy salad greens and fresh herbs.

Washing of produce in potable water can significantly reduce surface contamination by microbes. Water agitation is needed to physically dislodge microbes from produce surfaces and any re-used wash water should contain a sufficient concentration of sanitiser to ensure food safety microbes dislodged and suspended in the wash water can not cross-contaminate clean produce washed in the same water.

Use of sanitiser in wash water is a risk reduction step - not a ‘kill step’ (i.e. not a guaranteed lethal treatment). Waxy surfaces with fine hairs create hydrophobic characteristics and microbes on fresh produce surfaces may be protected by small air spaces, have developed biofilms or do not have sufficient contact with the sanitiser for it to work. The best strategy is therefore to minimise the risk of contamination occurring through farming inputs and practices.

The Freshcare Food Safety & Quality Code of Practice identifies the good agricultural and good worker hygiene practices needed for managing on-farm food safety for fresh produce. It contains risk assessments and practices for managing microbial contamination issues.

Unless a product is labelled as ready-to-eat (RTE), it is always recommended that, as a precaution, consumers thoroughly wash fresh produce in clean water before consumption - particularly fresh produce types that will not be cooked.

Sanitisers in wash water

Where there is a risk of cross-contamination from the water used to wash fresh produce, treatment of the water with sanitisers may control the risk. Sanitisers used on-farm for fresh produce need to be approved by the Australian Pesticides and Veterinary Medicines Authority (APVMA, website www.apvma.gov.au or phone (02) 6210 4700).

There are a number of chemical sanitisers and non-chemical sanitising methods that can be used to treat water and technical advice should be sought to ensure that the best option is used for the type of microorganism to be targeted. The common options include:

-

•Chlorine and Chlorine dioxide formulations

-

•Chloro-bromine compounds

-

•Iodine

-

•Ultraviolet light

-

•Hydrogen peroxide

-

•Peracetic acid

-

•Peroxy compounds (combinations of hydrogen peroxide and peracetic acid)

Use of ozone to sanitise wash water that is re-used is not recommended as ozone diffusion and concentration in water cannot be assured or easily monitored in real-time, thus ensuring water sanitation is maintained.

If using postharvest fungicide treatments after a sanitation wash step, check with the supplier that the sanitiser will not degrade or interfere with the fungicide application.

get the free

Adobe PDF Reader

computer can’t read PDF files?

Bacteria

Aeromonas hydrophillia

Bacillus cereus

Campylobacter jejuni

Clostridium botulinum

Clostridium perfringens

Enterobacter sakazakii

Escherichia coli 0157:H7

Listeria monocytogenes

Salmonella

Shigella

Staphylococcus aureus

Vibrio

Yersinia enterocolitica

Virus

Norovirus

Rotavirus

Hepatatis A

Parasite

Giardia lambia

Trichinella spiralis

Fasciola hepatica (Liverfluke)

Moulds and fungi should also be considered, as their production of natural toxins (e.g. mycotoxins such as aflatoxin) are chemicals that can cause serious health impacts.

Causes of microbiological contamination in fresh produce

Starting at the farm end of the supply chain, the best way to minimise the risk of microbiological contamination is to assess the risks from farming inputs, follow good agricultural practices and train workers in food safety practices. Unlike a food processing facility, the farmer does not have control over all the risks that might occur from wild or domestic animal intrusion into the crop or irrigation water supply.

There are a number of potential pathways for microbiological contamination of fresh produce from the farm through to consumption, including:

-

-faeces from or the remains of wild and domestic animals and human sewage contaminating water sources used for irrigating, pesticide application, harvesting, unloading, washing, top icing, hydro-cooling or cleaning

-

-untreated fertilisers and soil additives of organic origin used contacting produce directly or indirectly via the soil

-

-picking of produce that contacts or drops on to contaminated soil

-

-inadequate cleaning of picking containers and harvesting, grading and packing equipment contaminated by soil, decaying matter and faeces of rodents, birds and insects

-

-stacking of pallets, crates and bins contaminated with soil and faeces on top of exposed produce

-

-packaging and packing material contaminated with faeces from rodents, birds and insects

-

-handling of produce by infectious workers due to inadequate worker health control, toilet and hand washing facilities, poor personal hygiene practices, and sickness (e.g. communicable diseases such as Hepatitis A)

-

-leakage of contaminated water from recirculating cooling systems in cold rooms

-

-faeces from pests in transport vehicles, processor facilities, wholesaler facilities and retail facilities

-

-contact with contaminated water or equipment used for processing

-

-temperature abuse of chilled product

-

-handling of produce at retail by infectious consumers with poor personal hygiene practices

-

-cross-contamination from poor handling and storage of raw and cooked products at food service or home kitchen

All partners in the supply chain need to have food safety practices in place to ensure they manage the safety of products under their control.

The three major on-farm pathways of microbiological contamination of fresh produce are through the use of untreated fertilisers from animal manure sources, contaminated water sources used on produce or from workers with poor hygiene practices handling produce.

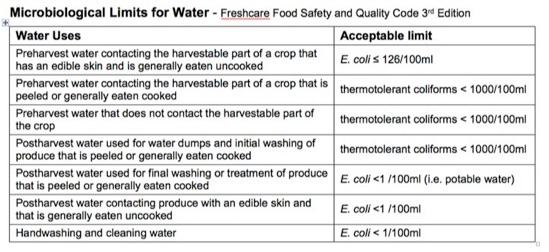

The Freshcare Program includes a series of preventive practices to ensure untreated fertilisers of organic origin (e.g. animal manures) are excluded from use well in advance of harvest dates, and specifies acceptable microbiological limits for water used in processes.

© 2015 Frontline Services Australia Pty Ltd | ABN 41 136 738 997 ACN 136 738 997 | E: info@frontlineservices.com.au